Tech-savvy generation propels Vander Vending ahead of the pack

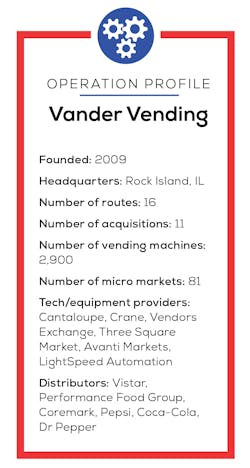

Vander Vending has grown from placing a single machine 13 years ago and battling it out with 30 competitors to staking its claim as one of the two leading independents among only a few remaining operators in the Quad Cities. Technology plays an increasingly important role, and the younger generation has stepped in to build upon the company’s legacy and drive it to new heights.

At the helm of the Rock Island, Illinois-based operation are founder Jerry Schreiner and his wife, Claudia, who credit their middle son, Cade, for his instrumental role in catapulting Vander Vending beyond its competitors.

As is the case with most vending operators, Schreiner stumbled into the business by happenstance. He had renovated his basement with all the bells and whistles for the ultimate entertainment space, including several classic arcade games. But upon completing the project, he found that two of the games did not fit.

So, Schreiner installed one of the coin-op machines in his brother’s bar and the other in a local pizzeria and became a coin-op amusement operator overnight. His day job was at Tyson Foods, where he worked as an electrical mechanic, which gave him a head start understanding the basic workings of the equipment.

But as he secured more locations, it wasn’t all he had hoped it would be.

“I learned that with amusements, we could get six bars all signed on for us to run dart or pool leagues and tie them all together, but then one bar wouldn’t be on board for one reason or another, and we couldn’t get that seventh location,” the operator recalled. “Equipment can be costly, and all that time to invest in securing five or six bars, and then, if the seventh won’t flip, it is a lot of wasted time.”

This frustration and less-than-stellar collections inspired him to instead try his hand at vending.

If at first you don’t succeed…

Schreiner purchased a fixer-upper snack machine and got it up and running at his first location. He purchased $500 worth of snacks at Sam’s Club, stocked it full and stored the extra product in the bottom of the machine.

And with this first machine, Vander Vending was born. It is named after the couple’s miniature schnauzer, which Schreiner picked because the dog’s mother had bitten off half of its ear. So, they named the pup after Evander Holyfield of boxing fame, who suffered the same fate, and shortened his name to Vander.

When the fledgling operator returned to restock the vender and collect his money a week later, he found a mouse had snacked on every single package in the machine, and the lid on the stored product was not sealed tight, so the rodent helped itself to all of those goodies as well.

“Mice don’t eat; they snack. It was like a cartoon skit. And then I opened the coinbox, and there was only $1, and right then, a guy came up and told me he lost a dollar in the machine, so I gave it to him,” the operator recalled. “It was a horrible first experience. But I’d drag my wife, Claudia, kicking and screaming, with a trailer to buy archaic equipment. I found machines for $300 to $400 on Craig’s List. There’s a lot of that while building a business, and it never works the way it’s supposed to! But I kept plugging away and putting them out. In reality, I probably paid $3,000 to $5,000 to move junk equipment around and, before long, took it to the scrapyard.”

Claudia worked part-time in the new venture while maintaining her job with former Congressman Bobby Schilling, until she joined her husband full-time in 2013.

Schreiner credits his experience as a mechanic electrician at Tyson Foods for helping to ease his way into vending with less of a learning curve than most.

“It was the best maintenance program hands-down,” he remarked. “From preventive maintenance to troubleshooting, it’s been very key to me being successful in vending. I also paid my competitor $75 to send his mechanic to show me how my first machine worked and was able to hit the ground running from there; the best $75 I ever spent!”

It wasn’t long before Schreiner was convinced that the only way to provide vending service to the highest standard and compete effectively was with an investment in the proper equipment.

From David to Goliath

Working primarily with Crane Merchandising Systems to provide state-of-the-art machines, equipped with cashless payment, telemetry and all the latest advances, Vander Vending was able to win over accounts from more established competitors.

A great deal of this growth developed as Vander Vending absorbed other small vendors that had been servicing the Quad Cities area for decades.

“It was difficult for the smaller vendors to operate with good service and low prices as our economy changed,” Schreiner recalled. “By growing the company, we increased our buying power, keeping prices low for our customers while maintaining the same personal relationship with our customers. Contrasting our company with corporate vendors is heavily weighted with pros and absent of cons.”

The long list of pros, according to Vander Vending’s founder, include that his customers play an active role in deciding what products go in their machines and have a larger variety, along with lower prices.

“As issues arise, you get a real person when you call our number with faster response time to remedy issues,” he added. “The money earned stays in the community, and our charities that we donate to are local, and in many cases, we have found that they have directly impacted some of the very same people who use the machines on a daily basis.”

Fresh Idea Foods started in 1955 as a Pepsi distributor and became a full-line vending company in 2003. As micro markets grew in popularity, the company added the self-checkout stores to its list of services. Challenged to find good quality, reasonably priced market fixtures that suited its needs, the company decided to design its own market fixtures and began using them exclusively. After several requests to buy its system, Fresh Ideas launched FrameWorks Displays to offer its fellow operators a quality, affordable, space-efficient and easy-to-assemble all-metal merchandising system.

Sprouse Distribution owned the Pepsi franchise and Fresh Idea Foods. It sold the Pepsi franchise in 2018 and its vending business to Vander Vending in 2019, but kept Frameworks, which its owners continue to operate out of Vander Vending’s warehouse. Vander Vending uses the fixtures in many of the markets it operates.

Micro market growth

Vander Vending opened its first micro market about five years ago “under duress,” in Schreiner’s words.

“A customer said she wanted one, but she didn’t like the company pitching it and wanted us,” he recalled. “I told them we’d do it, but to please be patient, and within 30 days, they had a micro market.”

When Vander Vending bought Fresh Idea Foods, it inherited some micro markets, and it has continually been building its own growing base of them, with some 80 in operation today.

“We love markets as much as our customers do,” Schreiner commented. “We design markets with the customer and customize them to be branded for the customer to build morale in their company. We work with them to decide what’s merchandised in them. If they’re successful, we are.”

Say ‘cheese’

Three years ago, Schreiner added a bright yellow “Big Cheese” branded food truck to his arsenal for special events and to offer locations something different on occasion to invigorate their employees’ lunch break. The Vander Vending food truck specializes in all things cheese, including gourmet grilled cheese, cheese dogs, cheese fries and cheeseburgers.

Reminiscent of the mouse in his first vending machine, procuring the truck was no simple task. “I bought it in Pennsylvania, so I flew there with one of my employees to buy it and to drive it back – what we thought would all be in one day,” he recalled. “It was sleeting and we were freezing, and the best we did was 40 miles an hour. We got to Indiana at 2 a.m. and stayed in a hotel. The next day was the day before Thanksgiving, and of course, the truck broke down. Then, when we finally got a tow truck, the driver couldn’t get his lift to work. I wondered if it was an omen, but it’s been a good additional offering that sets us apart.”

Keeping it fresh

Vander Vending purchases its food from Kitchen Fresh Foods, a USDA-approved preparer of fresh, prepackaged food for micro market, vending, convenience and event market segments. Located in Green Bay, Wisconsin, it offers more than 450 items on a rotating menu, which provides a wide variety of fresh products for Vander Vending’s customers.

“Everyone talked us out of running our own commissary, and we’ve been very happy with Kitchen Fresh Foods,” said Schreiner. “With fresh food, there’s always waste, and we try to be economical. I’d rather buy it than make it and make 50 cents or $1 and not throw away any more wasted food than we have to.”

Managers who care are key

The key to success when selling fresh food, and ultimately across the board throughout Vander Vending, has been to hire more managers who care what’s happening in the business, Schreiner stated.

Prior to micro markets, Vander Vending exclusively used Crane combo machines to merchandise cold food alongside beverages to manage perishability and waste. And the machines still have their place in locations that demand food but cannot support a micro market.

“Customers want machines to look full, but if they saw the actual sales, they don’t recognize the cost of doing business,” said Schreiner. That’s why Vander Vending requires a $1,000 monthly sales minimum for each micro market; otherwise, the account subsidizes the difference.

“Otherwise, we pull it if doesn’t perform and convert it back to vending machines,” Schreiner said. “You have to pay attention to waste and have good workers who report it. If not, you think the account is doing great until you eventually learn the truth.”

Give them reason to be loyal

Customer loyalty cannot be underrated in vending and is at the heart of Vander Vending’s success, Schreiner emphasized. He credits his wife, Claudia, for helping set and maintain the highest of standards.

For Vander Vending, that includes its guarantee to provide service within 24 hours and its promise to deliver the best products it can offer its customers across the Quad Cities, a complex of cities and surrounding communities at the Iowa-Illinois border, on the Mississippi River.

The COVID pandemic thankfully did not put too much of a strain on Vander Vending’s business since it primarily serves an industrial customer base of essential businesses that stayed in operation and fully staffed throughout. Many, including Amazon warehouses, even grew their workforces to keep pace with pandemic-related increased demand. And some new opportunities emerged with companies that have closed their cafeterias and want micro markets in their place.

“We lost some business as a result of the pandemic but, for the most part, we were very lucky that most of this area kept moving,” the operator said.

OCS upswing

Office coffee service is a small but important and growing piece of Vander Vending’s business. It first offered the service to its vending customers at the lowest possible price on coffee possible and focused on making its revenue from vending.

“But we didn’t realize how much could be made in coffee if we charge a fair price and offer exactly what they want,” Schreiner said. “We don’t want to gouge customers, but we’ve found we have to raise prices because everything is skyrocketing and who knows to what end. And we still have a lot of interest in our coffee program, and it’s something we’re focused on growing.”

During the early days of the pandemic, Vander Vending swapped many of its traditional coffee brewers for liquid concentrate and bean-to-cup equipment, including Newco, Bunn, Nestle and Cafection models that minimize or eliminate touchpoints, many of which “make every specialty drink in the book.” These machines have been well-received and further fueled demand for specialty coffee, opening doors for more business, according to Schreiner.

Labor and supply chain woes

“It wasn’t so much COVID, but the worker effect later on has had a repercussion on our bottom line,” the operator observed. “We have to pay people more who have less experience than people we had.”

“Keeping the right things coming into the warehouse every week is a struggle; there’s always something new our distributors are out of. Customers understand but only to a degree,” he said. “With Cantaloupe’s vending management system, each specific item has its specific place. If that item doesn’t exist one week, we have to enter a new one; you can’t just replace it in the machine. So it’s more time and money while we have these supply chain shortages. It’s probably a good time for people to develop new products while operators are more apt to try something new to fill the gap if it’s an appealing item.”

Another interesting outcome of these turbulent times is enormous interest in the vending business, according to Schreiner.

“Never before have I been so inundated with calls from people getting into the vending business. I don’t know if most realize how much work is involved, the technology, servicing the customer. We keep up,” Schreiner remarked. “A lot of guys are looking to get into the vending business because of desperation. I got into it because I wanted to build a business to best serve the customer and make money and leave a legacy for my family. People think it’s so easy when they walk through the warehouse. What many don’t understand is that if we lose a $100,000 account, we can quickly place the machines somewhere else to make money because of the reputation we have built.”

The operator emphasized that the only way to get more business is to take care of existing customers to the highest standards.

Customer first

“You’re only as strong as your weakest link. You need managers for checks and balances, because finding dedicated workers is not what it used to be,” Schreiner stated. “We all have the same issues. Even as we battle each other for accounts, we have to have standards, and customers will eventually come back if we lost them in the end because we always keep an eye on the customer. It’s still a moral dagger when I lose an account I spent so much time cultivating because of competitors that brought a few good sandwiches to woo them — that they wouldn’t even sell in a market, which is a deceptive sales pitch.”

“We try to be at the cutting edge of everything. We use Cantaloupe to track product and sales in real time and for prekitting, and we’re adding LightSpeed to make prekitting faster,” Schreiner said. “Almost every machine takes cashless payment. Some of our micro market kiosks accept gift cards with our logo that is available to US Connect members and helps build our brand. I won five key bids a couple of years ago because US Connect lets us compete at the national level. It also creates a network, so when I go to Vistar I can compare notes with other members.”

Additionally, Schreiner praised his Coca-Cola, Dr. Pepper and Pepsi bottlers for their support with the many branded venders they supply and his success selling their products.

Next generation

Other key employees who fall into that category are Luke Conger, head of maintenance, who was key to getting Vander Vending’s machines and micro markets on the Cantaloupe system, and Don Muse, general manager, who was instrumental with the Fresh Ideas Foods integration. Also, Mike Krup is another manager who Schreiner said has helped out tremendously, as well as Claudia’s father, Richard Freyman, who, at 78, finds a place for everything as the company’s project manager.

About the Author

Emily Cambriello

Emily Cambriello is a business journalist who has devoted much of her career to covering the convenience services industry. She is a contributing editor to Automatic Merchandiser/VendingMarketWatch.com.