In the vending business route trucks are the lifeline of the company. Without a good running truck, the accounts can’t be serviced and ultimately the machine goes empty, operators lose sales and may even lose an impatient account. This we all understand, but how about the inside of the truck, is it clean, are products placed in an orderly fashion? Think about this scenario; drivers are getting ready to service an account and the inside of the truck is visible to a passersby, do customers see order or chaos?

Truck layout

The truck should be carefully laid out with at least two shelves on each side for product, while saving the floor space underneath for the heaviest product, cases of soda. The driver needs to keep the truck orderly and clean throughout the day, breaking down empty boxes with a cardboard cutter and placing the trash in a box, preferably a large empty cup box. Another important item is where the collected money is kept during the day. If there is no safe on the truck, invest in one. A safe will be money well spent, keeping collections locked up and out of view from the passersby. Make sure the safe is bolted to the floor of the truck away from where product is brought in and out. For instance, when servicing out of the back of the truck, the safe should be in the front, and vise-versa.

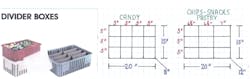

Now let’s look at how product is brought to customers. Do drivers use an old candy box, throwing in all the products they think they will need, all jumbled together? Remember they are dealing in food and even though it’s pre-packaged, they still need to treat it as food. A crumpled bag of chips or a smashed pastry becomes very unappealing when placed in the machine. Make the point that if they wouldn’t buy an item based on how it looks then neither will their customers. I would suggest that the operator make a small investment into durable, stackable plastic boxes with dividers. This will make everything easier to load and easier to pick up and place into the machine. And of course, the added benefit is how clean and organized this looks to the customer when the driver rolls in three or four stacked boxes with the product all separated and in good shape.

Notice that I said, “rolls in,” that is because I’m assuming that the driver is using a dolly to bring product into the accounts. Every truck should have a dolly assigned to it, what type is up to the operator, but I would recommend one that drivers can convert to a platform when they need to bring both snacks and soda to the account, allowing them to make one trip. Don’t let the cost of a good dolly deter the purchase, instead consider how much a workman’s comp claim for an injured back will cost in increased insurance premiums.

Vehicles are an essential tool to the vending operation. Keeping them professional looking and organized for fast efficient service is a key strategy to business success.

Servicing the account

With an organized, easy to use and professional truck setup, now it’s time to determine proper servicing of the accounts. I don’t know if there is a general rule of thumb as to when a machine should be serviced, but there are two extremes operators fall between. If an operator goes to service a snack machine and 30 out of 35 spirals are empty, the customer has probably had to call the operator for service. That may be ok if it happens once, but if that customer always has to call because the operator is waiting to get the most cash they can, that customer will soon be looking for another vendor. The operator may think they’re getting the most cash, but they don’t know how many sales were lost due to the items being sold out 3 days after filling. These all add up to lost sales and a reputation for bad service. The other extreme, of course, is going to a machine to find only one item sold out, with none of the others even close to selling out, making that service basically worthless.

Ideal: Half sold out

In order to come to a happy medium operators need to look at how many units were sold in each price point. Servicing a machine that has 40 to 60 percent of the units sold is a good option. The machine still has product in it and the driver is taking out a fair amount of cash for his or her trip. Ultimately, we all would like to service a machine with one or two products left in each spiral and no empties, but it’s important to realize that this is never going to happen. The best we can do is to get as close to this as we can, which is possible if an operator is using the service card the way it’s meant to be used. To see more about properly using the service card, visit www.vendingmarketwatch.com/10950871 for my article on properly servicing accounts.

About the Author

Dominic Finelli

Dominic Finelli is 43-year veteran vending operator in the Washington D.C market. Along with his partner/brother-in-law, John Sartori, he helped grow a family start-up, Custom Vending, to 30 routes. Finelli earned a degree in accounting from Benjamin Franklin University, was a 3-time recipient of the NAMA Chairman's Legislative Award and the 2004 Operator of the Year. Finelli served 23 years as a director of the MD/DC Vending Association, and 10 years as the president. He sold his vending company in 2011. Finelli can be reached at [email protected].