There are a number of things that help you run a better vending operation. Some seem to be common sense stuff. Then there are others that are learned over time through experience both good and bad. I’m going to try and give you some pointers for the small vending business owner that I learned by trial and error during the 43 years of working for a vending company. This is part two, which will focus on techniques to use in back of the house management. For more tips specific to the route driver, see Little things make a big impact, part 1 in the February issue of Automatic Merchandiser.

Keeping track

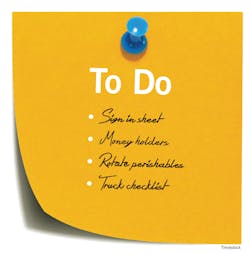

Now if you don’t already have this, create a sign-in sheet. This is done very simply by making columns and dividing them in two. Then label the two columns in and out with enough space to allow for a check mark for when items are taken out and returned. You can title the columns as Route #, Truck keys, Route keys, Change funds, Phone, Time in and Signature (from the person who gave out these items) and Time out and a Signature (from the one who took these items back). This serves a dual purpose, not only is there a record of the driver picking up these items and returning them, but you now have a better idea of when they reported for work and when they finished. Use this also for your mechanics for keys given to them. Place these sheets in a binder, a different sheet for each day and save them for future reference. This may all seem like a lot of work but once started, within a short period of time, it will become second nature and part of your operational procedures.

Counting currency

Do you count your collections, and if so, how much time do you spend straightening dollar bills so that they will go through your counter? We had the same problem and came up with a simple solution using materials we already had in abundance. We took the plastic fronts from our old machines which we were going to junk and cut them into pieces the size of a dollar bill. We rounded out the edges so that no one would cut themselves, and over time we were able to make hundreds. We then instructed our drivers to take them on their routes every day and at each machine when they took out the bills they were to sandwich them between two plastic strips and place 2 rubber bands around them to hold the bills in place before placing them in their collection bag. Now when the money is counted there is no time wasted on making the bills straight. Once you have enough of the plastic pieces, simply place them in a box next to the sign in sheet along with a box of rubber bands for the drivers to take every day. The cashier will save both rubber bands and plastic pieces and replenish the boxes, thus the cycle goes on each day, saving your cashier valuable time with just a small investment in rubber bands.

Deposits

While we are on the subject of collections, if you or one of your employees is taking the money to your bank, you must know that you may be playing with fire. Think about hiring an armored car company to take the money to your bank. This is the safest way to deposit your collections at a very reasonable cost. Believe me when I say that the peace of mind this will give you is priceless.

Throwaways

The vending industry throws away a lot of products that we are unable to sell due to the short shelf life. We always try to buy the right products but sometimes you can’t control the buying habits of your customers and what may sell at 80% of your accounts may not sell at the other 20%. What to do? If you don’t already have a plan in place, allow me to make a suggestion. Get together with your driver and come up with 2 or 3 of the best selling snack locations on each route. Instruct the drivers that when they go to a machine that has a lot of products that are not selling but have at least a 7 to 10 day shelf life left to take that product out and funnel it to those best selling machines. By doing this you may be able to sell most of the product that otherwise would have been thrown away because of the expiration date.

Truck maintenance

We had previously talked about setting up the inside of your route trucks, now we need to make sure to keep those trucks on the road in good condition. Set up a checklist for your drivers to fill out at least weekly or anytime they notice something wrong with their truck like bulbs out, bad tires, fluids low, bad windshield wipers, etc. Have them also write in the mileage each week so that you can track in order to schedule oil changes, and keep track of how many miles each route is traveling on a weekly basis. This will allow you to move accounts around to make sure each driver is traveling the shortest distance to service your accounts.

I hope that some of you can implement a few of the things I have talked about, but only if it fits your company. Remember that ideas are not good unless they are good for your company. As always, please feel free to contact me any time with questions and/or suggestions you may have at, [email protected].

About the Author

Dominic Finelli

Dominic Finelli is 43-year veteran vending operator in the Washington D.C market. Along with his partner/brother-in-law, John Sartori, he helped grow a family start-up, Custom Vending, to 30 routes. Finelli earned a degree in accounting from Benjamin Franklin University, was a 3-time recipient of the NAMA Chairman's Legislative Award and the 2004 Operator of the Year. Finelli served 23 years as a director of the MD/DC Vending Association, and 10 years as the president. He sold his vending company in 2011. Finelli can be reached at [email protected].