Best Practices for Protecting Margins from Rising Costs

As I write this article, the price of gas at the neighborhood Shell station is $3.29. Who knows what next week or next month will bring? The skyrocketing cost of energy is cutting into the profits of all American businesses, but vending and other delivery-based companies are particularly feeling the pinch. With razor-thin margins to begin with, operators are taking a big hit from rising fuel costs.

And if a 60 percent increase in the cost of energy wasn’t damaging enough, operators are facing rising healthcare and labor costs and lower manufacturer rebates. All of these factors combine to seriously hurt profitability. Fortunately, vending and OCS operators can adopt a number of "best practices" to mitigate the impact of rising costs and falling rebates. This article will take a look at what "best practices" operators can implement to stay profitable.

One key: reduce delivery trips

One obvious way of lowering fuel costs is to use less gas by reducing the number of deliveries. Doing this also makes better use of the driver’s time and provides more value to the operator for the same wages and healthcare costs.

If you or your route supervisors have not been optimizing your routes, let those rising costs be a catalyst to do it now! Although there are several ways operators can optimize routes, the best way is to look at certain "metrics" for each machine and plan on updating both the planograms and delivery schedules.

A modern vending software system will make collecting and analyzing the appropriate metrics much easier, but the job can be done without one. Start by looking at the most recent services at each machine, and consider the following metrics:

• Percent deleted — How empty was the machine when the driver arrived to service it?

• Percent filled — How full was the machine when the driver left it?

• Number of sold-out columns — The number of columns that were sold out.

• Number of sold-out products — The number of products (and not columns) that have sold out.

• Value of dollar sales (even if not collected).

The goal in fine tuning schedules and planograms is to service the machine when it is as depleted as possible with no sold-out products. A certain amount of sold-out columns may be acceptable because studies show you will only "lose" the sale if the product a consumer wants is not available.

Less service can mean better service

Many operators service a snack or soda machine when it is only 30 percent depleted, and it has sold out of one or more products. This is an opportunity to service the machine less often and provide better service. Here’s a strategy for doing so:

- Double up on the best selling two or three products that are selling out. On a "space to sales" soda machine, reallocate the space to the best seller(s) to accomplish this.

- Monitor the sell-outs for the next few services — they should be eliminated.

- Work to reschedule the machine aiming for a 40 to 50 percent depletion level. Typically, this will involve scheduling it for service at a 30 to 60 percent longer interval.

If collecting these metrics is difficult, or if a manual system is being used, then let the drivers collect the data. Ask them to write the following on each service ticket:

- How many products have sold out?

- Approximately how empty is the machine?

- The products that are selling best and how many columns of each they have allocated.

Oftentimes, just asking for this information will get your drivers focused on it. You will then be able to sort through this information and check up on your drivers.

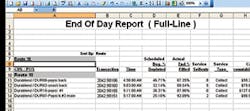

The latest software and technology solutions can automate much of the manual route scheduling process, using the following systems:

- Dynamic scheduling. This automates the delivery schedule each day based on user-defined parameters, such as number of sell-outs, percent depletion, or the number of days since the last service. Forecasting algorithms generated by data collected via a handheld the last time the machine was serviced helps the system build each daily schedule. If a machine doesn’t require servicing, why waste the gas — and the driver’s time — on a trip? Dynamic scheduling works with non-DEX as well as DEXable machines. Remote monitoring can make this work even better.

- Remote monitoring. This does require DEX, as well as a wireless or hard-wired network, to remotely enable the machines. This technology, which has been embraced by several operators over the last few years, allows the operation to optimize scheduling and merchandising by providing real-time sales data. It can be especially useful for distant locations that are costly to service. And with gas prices at $3.29 and rising, smarter scheduling can really cut back on those long drives.

Many operators using these techniques have not only reduced service visits, but they’ve also cut entire routes. That means they can add customers without adding staff, or they can reduce staff.

Software forecasting can Reduce inventory

Another way to lower costs and improve profitability is by reducing inventory. Software forecasting can be a real help here. Knowing what an account needs before a service visit allows the driver to carry only a single day’s inventory instead of the typical two and a half to three days’ supply found on most trucks.

Carrying less inventory has the added benefit of requiring smaller vehicles. One operator, who uses forecasting to prekit his accounts the day before a service visit, traded in his fleet of trucks for smaller, cheaper and more fuel-efficient vans. Another operator credits prekitting with allowing him to service 30 percent more machines in the same amount of time.

These data analysis tools in vending software also help vending operators reduce their inventory. With item-level tracking, operators receive actionable data on which products are hot and which are duds. There’s no point in stocking merchandise that a particular account doesn’t want. Eliminating unpopular products and maintaining a more efficient warehouse can have an almost immediate effect on the bottom line.

Provide More Value to the Same Customers

Instead of focusing on lowering costs, you can raise the top line by providing more value to your existing customers. One OCS operator I know moved from just selling OCS products to selling OCS, bottled water, office supplies and toiletries to the same accounts. He now carries over 4,500 SKUs (including napkins, first-aid kits, pens, Tylenol and Windex) and had to change his business process to efficiently deliver to these accounts.

Rather than doing traditional "off-truck" OCS deliveries, this company allows the salespeople (route drivers) to manage the account by tracking par levels and placing new orders each time they drop off supplies. Since the company "pre-sells" everything, the trucks can be prepacked with the orders with only what the driver needs from the 4,500-SKU warehouse.

The customer that used to order $80 worth of OCS products each month now orders an additional $60 worth of general office supplies. Since everything is prepacked, the delivery time (and cost) for the driver didn’t change at all.

A handheld software system can automate the preordering process, but companies can still make this work with manual carbon copy invoices.

Managing Account Profitability: you need data

According to Automatic Merchandiser’s most recent State of the Vending Industry report, the cost of products is rising faster than operators have raised prices. That means a lot of operators are saddled with unprofitable accounts. If you have a special "hook" into the account, you may be in a strong position to raise prices or lower commissions. Many operators will need rock-solid data to back them when asking for concessions, or asking will likely result in a "no."

Before you can approach your accounts, you need to have definitive data that demonstrates where you are. At a minimum, your P & L model should include money collected or invoiced, less the following: refunds, sales taxes, commissions, cost of goods sold, equipment depreciation, spoilage, service costs and overhead costs.

Some operators have even more detailed P & L analysis that takes into account the amount of time needed to drive to and service different machines. It is important to analyze the account as a whole because some machines may lose money as part of an overall profitable contract.

How to renegotiate commissions

If your best account analysis suggests you are not making a profit at an account, it is time to approach the manager and attempt to renegotiate prices or commissions. Here are some specific strategies for reducing commissions:

- If the account performs overall, but certain machines are not making money, ask to pull those machines or offer to continue to service them without paying commissions on just those machines.

- Stepped or "tiered" commissions can offer a

win-win solution for you and your customer. In

this way, you can pay a higher commission rate

on only the machines or locations that meet a predetermined threshold.

If the account is not profitable and is unwilling to negotiate, it is time to walk away without looking back.

When you need to renegotiate a contract to stay profitable (or when you are bidding on new accounts), there are certain things you can do to differentiate yourself from your competitors. The "hook" also can allow you to charge higher prices than your competition. Here are some examples of great value-added hooks:

- One operator recently beat two competitors at a large account by offering 6 percent commission instead of the 12 percent and 13 percent the competition offered, at the same prices. This operator offered to install remote monitoring equipment to provide better service and audited commissions. The prospect was happy to choose better service over a higher vending commission.

- Another operator has installed a cashless payment system that allows employees to charge "keys" using credit cards. The keys are accepted by cashiers in the manual food line and by all the vending machines. Recently, the operator asked to raise prices. While the customer wasn’t happy about a price increase, the operator was able to point out that the cashless system they offered was a unique service that many of the employees loved.

Improved Accountability holds the key to profit

If you are running a business with 7 percent profit margins, and you have a 3 percent cash accountability problem and a 1 percent shrinkage problem in your warehouse, you can increase your end-of-year take-home pay 50 percent just by fixing these problems.

A DEX accountability system will allow you to reduce cash accountability issues to within .01 percent. Without DEX, you can start tracking cash meters and reduce cash accountability significantly. Either way will help eliminate the problem of drivers running their own products through your assets.

There are no easy ways to track warehouse and truck accountability without doing the obvious — tracking what comes into the warehouse, moves to the trucks, and eventually makes it to machines and OCS accounts. The only way to do this effectively is with software and handhelds with bar code scanning. If you are not ready to move to a software system with handhelds, concentrate on cash accountability with cash meters and tackle the warehouse later.

None of us has a crystal ball, but we all know that competition will get tougher, and costs have made the business environment more challenging. Implementing best practices using fact-based data will allow you to stay ahead of your competition.

In addition, it will allow you to confidently leave an unprofitable account to your competition, knowing that you are coming out ahead in the end.