Vending operators face a declining economy and are looking for new ways to save money, grow sales, and increase profit. Many operators have profited and grown because of a direct investment in technology, but the benefits have historically been difficult to understand and measure.

Several operators have proven results with real numbers. My past articles have explored technology topics in significant detail, but I have never put together all the financial results in a return on investment (ROI) model.

This article will present the true measurable ROI when implementing and deploying vending management software and remote monitoring solutions.

For the sake of simplicity, we will not include consideration of cashless, but the good news is that cashless and remote monitoring solutions are being increasingly offered as one solution.

While there is no average vending operator, the ROI model in this article is based on financial information in the National Automatic Merchandising Association’s 2008 operating ratio report.

MODEL FOR ANALYSIS: A LARGE OPERATION

For purposes of demonstrating potential benefits, I will use a larger than average operation, as it more clearly demonstrates the financial benefits of remote machine monitoring. The company in this model has annual revenues of $7 million; individual annual route sales total $350,000, cost of goods are 49 percent, and baseline profit is $133,000 (1.9 percent of annual revenue.)

In order to calculate a full ROI, we need to understand: 1) the profit benefits that technology can provide, and 2) the full costs of implementing technology solutions.

Vending management software and remote monitoring can help increase profit in many ways, and some remote monitoring providers are offering Web-based features that have traditionally been offered by management software providers.

To keep the analysis simple, this article attributes certain benefits to each of these systems (vending management software and remote monitoring), and describes how the systems working together can provide the best overall return.

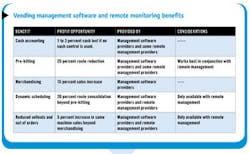

The chart above outlines the various benefits and how they are provided. For the ROI model presented, cash accountability, pre-kitting, and merchandising are modeled as benefits of a software system, while dynamic scheduling, reduction in sellouts and machine uptime are modeled as benefits of a remote monitoring system.

DEX ALONE CAN ELIMINATE CASH SHORTAGES QUICKLY

A software system should be able to provide several benefits, though some are harder to achieve than others. If you are utilizing DEX in most machines, you should be able to almost eliminate cash accountability shortages.

Assuming that the average company has a cash accountability problem of 2 percent, this benefit shows up in the profit and loss statement as a direct benefit to the top line with no increase in costs.

PRE-KITTING CAN ELIMINATE ROUTES

Pre-kitting — where the warehouse “pre-packs” bins for each snack machine and pre-stages orders for drink machines — makes drivers much more efficient by:

- Eliminating the “counting trip”, and

- Eliminating all the shuffling around in the back of

the truck.

Pre-kitting also minimizes inventory on the truck, and some operators have even been able to switch to much smaller delivery trucks.

For the ROI model, we assume a conservative annual truck cost (driver, gas, insurance, maintenance, and truck depreciation) of $70,000 and assume that moving to pre-kitting allows the business to consolidate 25 percent of its routes. In other words, a 20-route company will only need 15 routes after switching to pre-kitting.

Pre-kitting also requires additional warehouse help, but oftentimes, companies use part-time or low cost

help for this.

For the model, we assume conservatively that a single additional warehouse can pre-kit four routes at an annual cost of $30,000 per year.

ITEM-LEVEL TRACKING YIELDS HIGHER SALES

Finally, our model includes a 15 percent increase in same machine sales due to tracking “item level” sales in the machines and using sophisticated merchandising software to know what to put in the machines. In this area, I have seen huge variances among operators. Those with experienced commissioned drivers will see less of an increase, while those with high driver turnover will see a higher return.

It is worth noting that sophisticated software tools have been used in retail for 25 years, and no retail store would consider letting the stock person determine how retail shelves are merchandised, yet this is common practice in vending where vending drivers arbitrarily decide product mix.

While the model includes a 15 percent increase in sales, this does not all go to profit because of a cost of goods sold (COGS) modeled at 49 percent.

‘SOFT’ BENEFITS BRING ADDITIONAL SAVINGS

There are other “soft” benefits provided by software systems such as accurate profit and loss (P&L) analysis, reduction in inventory shrinkage, and spoilage reduction, especially in cold food machines. These benefits are not included in the model.

The model attributes two main benefits to remote monitoring, but there are many other “soft” benefits not included in the model.

Dynamic scheduling allows the business to service machines only when they need it based on thresholds or profiles that are entered in by machine type.

As an example, a snack machine can be scheduled for service when any of the following criteria are met: $150 in the machine, two or more sold out products, four or more sold out columns, or 50 percent product depletion.

Newer dynamic scheduling systems can also take into account geographic proximity and machine banks to optimally plan each route.

There are many ways to measure the benefits of dynamic scheduling — for example, same machine collections usually increase, sellouts are reduced, etc. The model shows the benefits as an additional 20 percent route consolidation above the benefits provided by pre-kitting.

Remote monitoring systems also provide machine alerts for things like bill jams, power losses, etc. I have combined the reduction of sold-out columns from dynamic scheduling and increased machine uptime from alerts into a conservative 5 percent increase in same machine sales.

The following “soft” benefits for remote monitoring are substantial and are not included in the model:

- Remote monitoring (and end customer Web-based reporting) is a great differentiator in competitive bids and can allow the operator to win accounts without necessarily offering the lowest price or highest commission.

- Customers appreciate the alerts feature and the ability to provide proactive service.

- Many remote monitoring solutions also include a cashless option which can increase same machine sales, especially where vend prices are $1.75 or higher.

- Remote monitoring can make pre-kitting more accurate, which can be very important for unpredictable public locations.

Before moving on to the costs associated with implementing these solutions, I want to point out that the model assumes that either management software by itself or management software with wireless installed on all the machines.

DYNAMIC SCHEDULING OFTEN REQUIRES REMOTE MONITORING

In reality, customers are likely to initially deploy remote monitoring at only certain machines or accounts. Except on bottler routes, I have seen little evidence that dynamic scheduling can be effectively implemented without wireless devices installed on all machines on the route — so the additional route consolidation would be hard to achieve without wireless fully deployed.

What are the costs of implementation?

COSTS TO CONSIDER

There are some obvious costs associated with implementing software and remote monitoring, starting with the upfront and ongoing costs associated with these systems. To come up with the costs for software and wireless hardware, I use “worst case” numbers based on what is publicly known from various solutions providers.

I believe actual costs will be lower, but the model still proves itself with conservative numbers.

To keep the model simple, I have included $70,000 in salary for a dedicated project manager and assume that he or she stays with the company after implementation.

BENEFITS REQUIRE A FULL YEAR’S IMPLEMENTATION

It takes the entire first year to roll out the management software and the wireless solution to receive the full benefits. Hence, in the first year column shown in the chart, I account for 50 percent of the benefits that will be fully achieved in following years. I have taken the entire cost for software licensing and hardware (wireless and DEX retrofit boxes) in the first year.

In reality, most companies will choose to finance many of these costs. This will help the first year payback, while slightly increasing costs in following years.

Finally, first year costs may be underrepresented since most companies deploy service technicians to install the wireless hardware in the machines. In addition, travel costs will be incurred, especially at large, multi-branch operations.

The chart on the preceding page shows the baseline profile, and then the savings and ROI after software and remote monitoring are deployed.

The baseline profile assumes that nothing is

implemented, so the results do not change over the

different years.

REMOTE MONITORING DELIVERS QUANTIFIABLE RESULTS

No model can be 100 percent accurate. The model in this article attempts to strike a balance between simplicity and taking most things into account. A more accurate and complicated model should further break down some of the cost assumptions previously noted.

The charts presented in this article are designed to demonstrate how remote machine monitoring, in conjunction with vending management software, can improve financial results. For those readers interested in a more comprehensive analysis, I have prepared a spreadsheet that goes into greater detail and covers five years.

Readers who are interested in reviewing this comprehensive spreadsheet can contact me directly.

The bottom line, however, is that even if you assume your operation is better than the baseline and the benefits you achieve will be lower, demonstrable operating profit improvements still exist when deploying software and remote monitoring.

If you include any of the soft benefits mentioned but not included in the model, technology investments can go a long way towards solving a major problem in our industry today: the lack of profit.

These technology solutions have another industrywide benefit — they make vending a more robust, reliable and viable alternative to convenience stores, and improve the consumer experience in vending.