DEX has revolutionized the way the vending operator can do business. It captures lots of data from the vending machine, automatically. Then vending management systems can download the data and sift through it, presenting it in ways vending operators can readily understand and use to increase profitability.

An individual operator's level of technology and operational focus greatly determine which type of report from the vending management system is most advantageous. However, the reports mentioned most often focus on three topics: cash reconciliation, product merchandising and route efficiency.

"There are different levels of evolution," said John Davies, owner of Vendsys and Synectic Software Solutions. In his experience, operators using less sophisticated systems, such as reading cash meters manually and using spreadsheets, want to formalize their cash accountability and better manage product per machine with plan o grams and prekitting. "There's a lot of interest in prekitting," said Davies. "It ensures more efficient route operations and greater control over route operations."

Cash accountability will include the cash variance report, which shows what the operator collected against what the system reports was sold. "The report shows the vending cash meter, but also assures the product is going through the machine, so it's also an inventory report," said Davies. Other critical reports are inventory reconciliation (how products travel from the warehouse thru to the machine) and a waste report, which includes rates of product spoilage and if the product is making it back to the warehouse for disposal. "There needs to be cash accountability, but also an accountability as far as products," he added.

One key report VendSys customers rely on is the location profitability report. It tallies the sales value of the location with the recorded waste, commission and visitation cost (which includes the labor component of servicing that location). The report supplies an overall profitability or contribution number. "It's a drill down format report," said Davies. "The operator can look at the individual route and see its contribution, then drill down to the account level, then down to the machine level and then down to each individual product."

Merchandising report a must

"One of the most useful reports shows how much of each product has sold in the machine," said David Robinson, owner, Robinson Vending Corp. in Bridgewater, Mass. Robinson uses the VendSys system and said the reports are easy to read. He uses the product sales data in many different aspects of running his business including, driving sales and marketing. One example is when a customer wants a certain type of product to stay in a machine. "We can show only five sold this last month," said Robinson.

Scheduling efficiently

Reports that allow dynamic scheduling and prekitting are quite popular to maximize efficiency. Anant Agrawal, chief marketing officer at Cantaloupe Systems, said the dynamic scheduling report shows which machines need servicing, where the machines are and the service required. "Most operators run the reports the day before the driver is going out into the field," said Agrawal. "It's no longer a static schedule." This means the route may be different every day.

A prekitting report shows which products are needed to fill the machine. It's important for obvious reason, but Agrawal said operators use this report in different ways. Someone new to the system may run the prekitting report and give it to the drivers to pull from the truck at a location. Others will give it to the warehouse personnel who round up to the nearest case and load the cases into the truck. The most efficient way, however, is to have the warehouse personnel pick the products from the report and put it into a bin for each location. "One big advantage is so they (operators) don't have excess product on the truck," said Agrawal.

Cantaloupe also offers alert reporting, which reports situations like equipment malfunctions. This can be a report on the computer, or for immediate problems, a text message to the service tech.

A report Agrawal believes will be very popular with operators is a new one called Dynamic Par. This report will analyze the slow moving products and adjusts the fill count based on the service schedule. For example, the current software wants to fill a column to it's capacity (12 products). If the column never sells out, there's no need to always fill it to 12, six products might suffice.

"It is inefficient to always fill the column of slow movers," said Agrawal, This is especially true if the product doesn't have a long shelf life. "The purpose of scheduling, prekitting and merchandising -- if coupled well -- should be to have one unit left in every column when the route driver services the machine. That's the perfectly depleted machine," said Agrawal.

Must be interactive

Glenn Butler, CEO of CTO Services, LLC, has been helping operators utilize vending software reports for many years. When an operator is looking at sales, Butler recommends a merchandising tool, or a program that takes the guess work out of a report. "With a tool like the (Streamware) merchandiser – the system can actually make suggestions, said Butler. The tool recommends operational changes based on the data collected.

According to Butler, the best reports provide interactive drill-down analysis instead of paper or general reports that cram in too much data "As an example, a user might run a cash accountability report and see that route 101 was short $150 today. Instead of having to run another report or change the settings, a drill down system would allow the user to simply click on route 101 and then it would expand to all the services done by route 101 today," he said.

Easy to understand

Top priority for Stu Reimann, marketing manager at D&R Canteen in Rochester, Minn., is how easy the report is to use. "No one wants to spend 45 minutes on a report to make a determination," said Reimann. "The information should be right there for you." In the case of a performance report, Reimann wants to know at a glance what the customer is buying. That gives him the knowledge of how to increase sales with similar products or more facing as well as service the machines less often. Another report Reimann finds useful is the MEI Easitrax's machine ranking report. It shows him the top performing machines as well as the bottom machines. He uses this information to decide when to swap out new equipment at his best locations and when he can take a poor performing machine and put it in a new location, avoiding having to purchase a piece of new equipment.

Cash accountability reports are also vital to Reimann, when he's monitoring revenue. "The best report really depends on the application," he said.

A reporting feature Reimann finds essential to his business is the ability to customize or write some of his own reports. "MEI has a lot of pre-existing reports, but they'll orient it to your specific needs," he said.

Overview shows problems

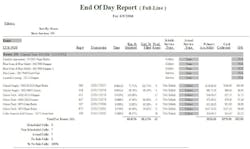

Giving operators a snapshot view of the day's activity is important in a report, according to Lee Brooks, director customer relations at Crane Streamware. The snapshot should include the locations scheduled for service that day, the machines actually serviced, time of service, how full the machine was upon arrival and after servicing, number of sellouts, sales accountability, and actual cash collected. Having all this information in one place allows an owner to spot inconsistencies. He or she can then drill down further into the money or inventory accountability reports, which Brooks said are also popular among operators, to determine what is happening. A machine showing a shortage of cash might look like an employee theft, but could be a coin mech not being filled one day or the result of an overage for that exact amount the last time the machine was serviced. "You always have to look at the history before you can determine if you have a problem," said Brooks.

"The vending software program is aimed at putting control back in management's hands," said Brooks. "The only way to do that is with data." The data can also open a dialogue with employees. Based on the report, an owner might want to ask a driver why he's not following his preset schedule -- and show the driver the report the schedule is based on.

The Streamware "snapshot" report, called the end of day report, can be especially useful when an operator is using a static service schedule. According to Brooks, operators can go in at their discretion, review the end of day report and make necessary adjustments. Using a dynamic schedule can save resources, but requires a scheduling manager to review it and keep it going.

Brooks admits there's a learning curve, just as with any new system. Streamware offers prescribed training as well as help documents. "For the first year we tend to get calls," said Brooks. "After that, those who use and maintain the system are very good with it."

Bradlee Whitson, operations manager at K&R Vending Services in Bridgeton, N.J. also appreciates getting an instant overview of his business. "With so many things pulling at our time, we have found it invaluable to be able to quickly bring up a screen to see how a driver is doing.," said Whitson, who uses Validata's RouteSupervisor report. It is an overview of what occurred at each stop, including the time each machine was serviced, route exceptions and compliance as well as access to truck inventories.

Route Supervisor has allowed us to help try to figure out the “how” and “why” a problem has occurred," said Whitson. He recently found a driver having trouble with his inventory -- the numbers were off. Route Supervisor showed the driver was loading by units, but entering them as cases. "By using Route Supervisor, we were able to show the driver step by step where the problem was coming from and then get the issue fixed," added Whitson.

Reports are tools for operators. No matter which vending management software is chosen, using it effectively means understanding the report, making the necessary changes and verifying the success of those changes. It's also important to drill down through a report for more information when something looks amiss.

For more information

Cantaloupe Systems, 855-956-7333, www.cantaloupesys.com

Crane Streamware, 800-4-STREAM, http://streamware.com

MEI, 800-345-8215, www.meigroup.com

Synectic Software Solutions/VendSys, 617-934-1775, www.synecticssi.com

Validata Computer & Research Corp., 334-834-2324,www.validata.com